While the world dreams of running on batteries, the automotive industry is tackling one of the world’s most significant impediments to an electric future: Battery recycling.

Battery recycling currently has two extraction methods for renewing materials and eliminating toxic waste (Head over to our article for a complete breakdown of the current extraction processes). Both ways are less sustainable long-term – and far from efficient.

To make matters more complex, ScienceMag states that business models connected to battery recycling can be shaky at best, with many operations resorting to selling the extracted ore to stay in business.

According to WeForum, several companies are coming together to create new solutions for an electric future that won’t be built on the husks of exhausted batteries – and they each have their own system for sustainability.

Redwood Materials – based out of Nevada – uses the traditional methods of hydrometallurgy and pyrometallurgy to extract cobalt, copper, and nickel from drained batteries. The extraction process results in a pile of glue, plastics, and metal released to a landfill or dissolved in a pool of acid.

Li-Cycle, a company that focuses exclusively on lithium-ion battery recycling, prefers the leaching method of hydrometallurgy – and has made further claims that they are capable of recovering more than 95% of materials in a refined process patented by the company.

UK-based company Aceleron has a whole different approach up its sleeve. “The reason why we have such a challenge today with reusing a lot of batteries,” says co-founder and CTO Carlton Cummings, “is actually that many of them were not made with the next stage of their life in mind.” Aceleron focuses on creating batteries that are easier to disassemble at the end of their life, creating a more easily accessible market for recyclable materials.

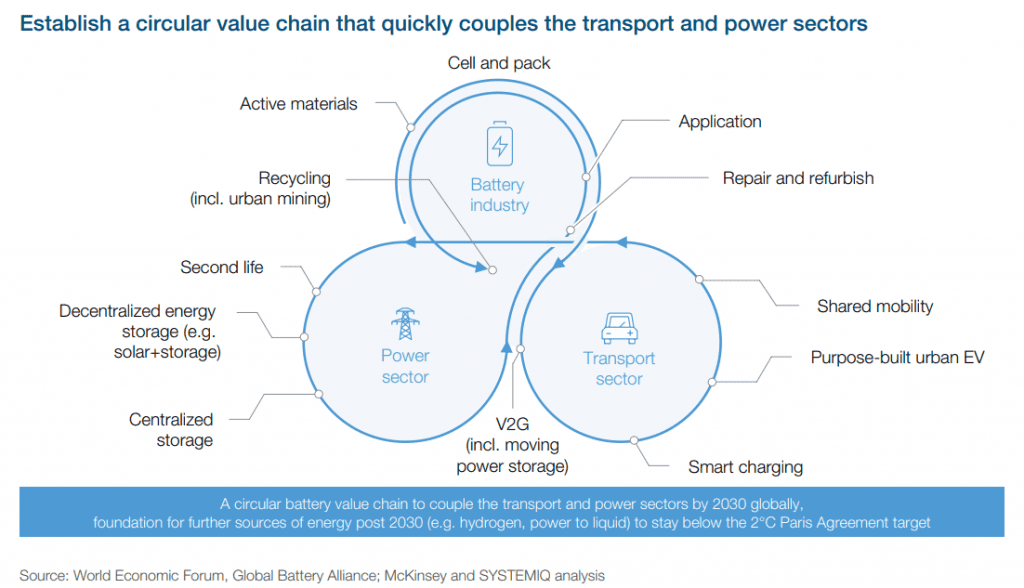

World Economic Forum’s Global Battery Alliance (GBA) aims to create a circular battery value chain by 2030. This chain will combine automotive and motor industries with power sectors to extend battery life as long as possible, creating maximum efficiency with minimum waste.

With electricity swiftly becoming the bandwagon that barrels into the future, time will tell if we will meet the deadlines on battery sustainability and recycling efficiency.

Source: MotorbikeWriter.com